MD Series Brass Universal Cooling Line used for connecting coolant lines to molds and dies on indection For Mold Quick Coupling

MD Series – Universal Mold Quick Coupling For Cooling Line

Single/Non Shut-Off Quick Couplings (Optional For Valved Coupler/Socket)

Industry Standard

MD Series couplings comply with Parker Moldmate Series

Interchanges With

Parker Moldmate, DME Jiffy-Tite – Jiffy-Matic, Rectus 86/87/88, Tomco MC, Foster FJT, Hansen Flo-Temp, Dixon CM Series

Features

- Available with or without valves in the coupler. Non-valved couplers have minimum flow resistance for maximum cooling.Valved couplers shut off automatically upon disconnect.Valved couplers can be used with either valved or non-valved nipples. A valved nipple, however, must be used with a valved coupler.

- Nipples are designed to be recessed below mold surfaces to provide more efficient storage of molds and prevent damage to the nipple.

- Widest choice of end fittings available, including straight, 45° or 90° with Standard Hose Barb or Push-On/Push-Lok Barb for easy installation.

- Couplers and nipples are made of corrosion resistant brass, and valved couplers or valved nipple have a Fluorocarbon O-ring on poppet and Silicone interface seal as standard for use with water glycol type fluids commonly used in heat transfer systems.

- Silver colored sleeve designates valved coupler.

Applications

MD Series couplings are specifically designed for connecting coolant lines to molds and dies, on injection molding machinery in the plastics and die casting industries. MD Series couplings significantly reduce machine downtime by providing fast and easy connection of coolant lines during mold changes. Their short nipples can be recessed below the surface of the mold for more efficient storage of molds. MD couplers are available with or without valves in the female half. Non-valved couplers provide maximum flow for efficient cooling. Valved couplers shut off when disconnected.

Selection Guidelines

- MD couplings are designed for a maximum working pressure of 300 PSI. Most thermoplastic and thermoset heat transfer systems have pumps which provide relatively high flow rates at relatively low pressures. Water and water glycol(anti-freeze) systems usually have capacities ranging from 10 to 40 gpm, with most from 10 to 15 gpm.Normal medial opening pressures are 20 to 60 PSI. However, their flow rates are usually much higher, requiring the total volume of oil to be circulated at least once per minute.

- The number of hose connections in a single mold system results in a cumulative pressure drop. Please note the Pressure Drop vs. Flow Rate chart provided, to select the appropriate.

- Temperature is another important consideration. MD couplings with their standard Silicone seal have a temperature capability of -54°C ~ +200°C. Rapid deterioration of the seal and leakage may result if used beyond these limits.

- Extemal conditions of temperature, corrosive atmospheres, and other abnormalities may affect coupling performance and must be considered when selection is made.

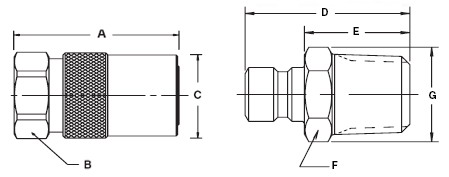

| Body Size | Coupler P/N | Nipple P/N | Thread | A | B | C | D | E | F | G |

| 1/4″ | MD-S200 | MD-P251 | 1/8″ | 1.15 | 0.56 | 0.71 | 0.94 | 0.54 | 0.44 | 0.51 |

| 3/8″ | MD-S300 | MD-P352 | 1/4″ | 1.84 | 0.88 | 0.96 | 1.34 | 0.74 | 0.56 | 0.65 |

| 1/2″ | MD-S500 | MD-P554 | 1/2″ | 2.02 | 1.12 | 1.21 | 1.70 | 0.94 | 0.88 | 1.01 |

(INCH)

Standard Thread: NPT(F) Thread, Optional For Valved Coupler/Socket

Standard Material: Brass (Steel Also Available for Nipple)

Specification

| Body Size (inch) | 1/4″ | 3/8″ | 1/2″ |

| Rated Pressure(PSI) | 300 | 300 | 300 |

| Flow (GPM) On 7.0 PSI | 3 | 9 | 15 |

| Seal Material | Temperature Range | ||

| Silicone | -54°C ~ +200°C | ||

| Viton (only for oil based media) | -10°C ~ +200°C | ||