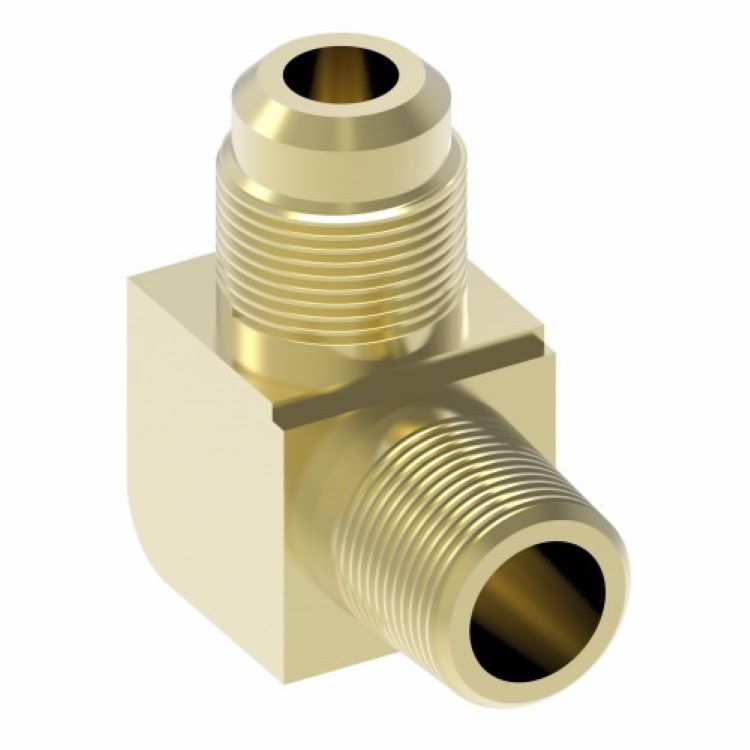

Brass Fittings Factories – Brass Fittings SAE 45° Flare Adapters – Sabe Machinery

Brass Fittings Factories – Brass Fittings SAE 45° Flare Adapters – Sabe Machinery Detail:

Applications

LP and natural gas, flammable liquids, instrumentation, refrigeration, power steering, hydraulic and pneumatic systems. Used on low, medium and high pressure lines under the most adverse conditions, compatible with copper, brass, aluminum and steel hydraulic tubing that can be flared.

Features

1.Construction – Two piece body and nut, straight barstock & forged fittings.

2.Good Vibration resistance – use long nut when greater vibration resistance is required.

3.Conformance – Heavy duty flare fittings are manufactured to SAE specifications, Meets specifications and standards of ASA, ASME, SAE, and MS (Military standards).

4.Reusability – Can be assembled and re-assembled repeatedly & Resists mechanical pull-out.

Specification

1.Temperature Range: -65°F to +250°F (-53°C to +121°C) range at maximum operating pressures.

2.Working Pressure: up to 2000 psi depending on tube size. Will withstand burst pressure of standard tubing – up to 5000 psi with bundy-weld (double flared) and 3500 psi with copper tubing, depending on size. Obviously, Temperature and type of tubing used are important factors.

Installation Instructions

1.Cut tubing to desired lenght. Make sure all burrs are removed and ends are cut square.

2.Slide nut on tube. Threaded and “A” of nut must face out.

3.Flare end of tube with a 45° flaring tool. a-Measure flare diameter b-Examine flare for excessive thin out.

4.Lubricat threads and assemble to fitting body. Nut should be turned hand out.

5.Tighten assembly with wrench until a solid feeling is encountered. From that point, apply a one-sixth turn.

Click Here For Overview Of SAE 45°Flare Fittings & Adapters

Product detail pictures:

Related Product Guide:

We believe that long term partnership is a result of high quality, value added service, rich experience and personal contact for Brass Fittings Factories – Brass Fittings SAE 45° Flare Adapters – Sabe Machinery, The product will supply to all over the world, such as: New Zealand, South Africa, Romania, We adopted technique and quality system management, based on "customer orientated, reputation first, mutual benefit, develop with joint efforts", welcome friends to communicate and cooperate from all over the world.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.