BJM Stem To Male Tube to Pipe Brass One Touch Fittings

| Mod. | G | D | H | T | L | SW | Weight (g) |

| BJM-M04-M5 | 4 | M5 | 4 | 16.5 | 24.5 | 8 | 3 |

| BJM-M04-G02 | 4 | Gl/8 | 5.5 | 16.5 | 27.8 | 12 | 10 |

| BJM-M05-G2 | 5 | Gl/8 | 5.5 | 18 | 29.3 | 12 | 9 |

| BJM-M05-G4 | 5 | Gl/4 | 7 | 18 | 31 | 14 | 11 |

| BJM-M06-G2 | 6 | Gl/8 | 5.5 | 18 | 29.3 | 12 | 10 |

| BJM-M06-G4 | 6 | Gl/4 | 7 | 18 | 31 | 14 | 12 |

| BJM-M08-G2 | 8 | Gl/8 | 5.5 | 20.5 | 31.8 | 12 | 12 |

| BJM-M08-G4 | 8 | Gl/4 | 7 | 20.5 | 35.5 | 14 | 13 |

| BJM-M10-G4 | 10 | Gl/4 | 7 | 23 | 36 | 14 | 16 |

| BJM-M10-G6 | 10 | G3/8 | 8 | 23 | 37.3 | 19 | 25 |

| BJM-M12-G6 | 12 | G3/8 | 8 | 24 | 38.3 | 19 | 25 |

| BJM-M14-G8 | 14 | Gl/2 | 9 | 28 | 44 | 22 | 59 |

Interchangeability for reference

Parker : 68PLMSP-4M-M5 68PLMSP-4M-2G 68PLMSP-4M-4G 68PLMSP-6M-2G 68PLMSP-6M-4G 68PLMSP-8M-2G 68PLMSP-8M-4G 68PLMSP-8M-6G 68PLMSP-10M-4G 68PLMSP-10M-6G 68PLMSP-10M-8G 68PLMSP-12M-6G 68PLMSP-12M-8G 68PLMSP-14M-8G

Eaton/WeatherHead :1180x4Mx2PP 1180x5Mx2PP 1180x6Mx2PP 1180x6Mx4PP 1180x8Mx2PP 1180x8Mx4PP 1180x10Mx4PP 1180x10Mx6PP 1180x12Mx6PP

Midland :

Camozzi :

attention please :Quotations and delivery of non-stock items supplied on request. Configurations and dimen sions subject to change without notice.

Metal/Brass Push-In Fittings

Features

- Simply to install & uninstall with no tools.

- Stainless steel tube locking mechanism.

- Thread sealant on taper threads, O-ring face seal on G threads.

- NBR as the standard sealing material,other materials are available upon request.

- Nick plated is standard for bass surface treatment, ensure anti-corrosion and anti-contamination.

- Reuseable-Can be assembled and disassembled repeatedly. (recommend to cut the surface-damaged part of tube)

- Thread: BSPP, BSPT, NPT (Please contact us for other styles)

Construction

Specification

| O-Ring Seal | NBR (other materials are available upon request) |

| Gripping Mechanism | Stainless Steel |

| Temperature Range | 32° F to 176°F (higher temperature are possible with special O-rings) |

| Pressure Max | 230 PSI (mainly limited by tube’s enduring) |

| Vacuum Duty | 29.5 Inch Hg |

| Media | Compressed Air |

Note: These meant only as a guide to aid in design. Field testing should be performed to find the actual values for your application.

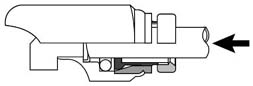

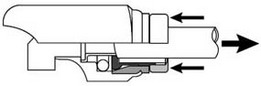

Installation Instructions

|

|

| Figure 1 | Figure 2 |

To connect tube (see figure 1)

- Cut tubing squarely–maximum of 15° angle allowable.Use of tube cutter (PTC) is recommended.

- Check that port or mating part is clean and free of debris.

- Insert tube into fitting until it bottoms.Push twice to verify that tubing is inserted past collet & O-Ring.

- Pull on tubing to verify it is fully inserted.

To disconnect tube (see figure 2)

- Simply press release button, hold against body, and pull tubing out of fitting.